EXECUTIVE SUMMARY

Optimizing Connected, Resilient Supply Chains in 2024

At the same time, with ongoing supply chain interference causing costly disruption to manufacturing operations, manufacturers are focused on finding ways to increase supply chain resiliency. Universal interest in generative AI (Gen AI) has fueled new solutions with the potential to solve many of the challenges facing manufacturers while maximizing the benefit from industry investment—in fact, Gen AI is embedded across all of Deloitte’s Top 5 Trends for the manufacturing and supply chain industry in 2024.

With investment in the right digital and GenAI-powered technology, manufacturers of all sizes, from smaller organizations to large global companies such as Schneider Electric, can build a connected supply chain with the insight and confidence to adapt quickly. Robust, scalable, and intelligent solutions such as ServiceNow’s workflow automation platform can help manufacturers embed resiliency into their supply chains and increase collaboration between suppliers and manufacturers, mitigating risk and minimizing disruptions.

Optimizing Connected, Resilient Supply Chains in 2024

Biographies

Context

Key Takeaways

Addressing product stagnation, labor scarcity, and quality matters remains a high priority, but the introduction of new tools, driven by technology advances such as GenAI, offers great potential for solving these challenges. Those manufacturers that have identified ways to leverage both existing resources and new processes, and to take advantage of AI-driven digital technology, will likely be better positioned to overcome these headwinds and move forward with greater speed and agility.

Over the past year, GenAI has matured significantly as the industry has gained greater understanding of GenAI’s capabilities and how to use GenAI ethically—though there are still many unknowns. With growing opportunities for leveraging GenAI in the business, it is critical for manufacturing businesses to identify the best and most effective use cases for leveraging GenAI to yield the greatest return on investment.

Robust investment and continued headwinds are driving five key trends for the manufacturing and supply chain industry in 2024, all of which are enhanced by GenAI capabilities:

1. Navigating persistent talent obstacles.

4. Aftermarket services as a potential differentiator.

4. Aftermarket services as a potential differentiator.

– Lindsey Berckman, Principal, Deloitte Consulting LLP

Improving supply chain resiliency is a key focus for manufacturers.

Note: The prepandemic average was calculated from lead time values taken from January 2015 to December 2019.

Source: Deloitte analysis of the Purchasing Managers’ index reports published by the Institute for Supply Management.

Disconnection creates chaos

Advancements in technology have enabled solutions that help provide proactive risk identification and management in the end-to-end supply chain.

With increased digitization has come an onslaught of cybersecurity attacks, especially on operational technology (OT) infrastructure. The impact of a

READ MORE

successful attack deep into the supply base is driving increasing need for cybersecurity capabilities to be incorporated into the product itself, across platforms, and in different organizational areas as new products are brought to market.

In addition to connected systems, standardizing on a common and proven aggregation and predictive analytics system, such as ServiceNow, can avoid many of the cybersecurity matters that stem from multiple disparate systems having to connect to one another.

Employing a common, trusted, and scalable platform for data collection and management also supports collaboration among all supply chain stakeholders by reducing data-sharing friction and customization requirements.

LESS

These are connected solutions that:

- Take into account data from multiple sources across the supply base

- Aggregate information in a centralized single source of truth

- Apply intelligence to help predict and alert on matters before they occur

– Ajay Chavali, Managing Director, Deloitte Consulting LLP

Collaboration is a foundational element to drive resilience and agility in the supply chain.

– Allen Hackman, AVP/General Manager, Manufacturing Industry Vertical, ServiceNow

Capabilities of the connected supply chain

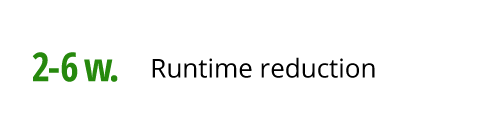

SC Optimization

App Store

Capabilities

- Dynamic Network Optimization

- Tactical Network Optimization

- Integrated Improvement Tracking

- Interactive Visualization of Transport Networks

Benefits

- 2-6 w. / Runtime reduction

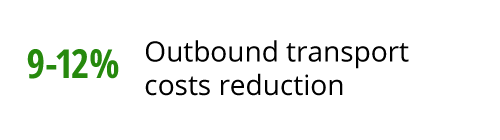

- 9-12% / Outband transport costs reduction

- ~10% / Total logistics costs reduction

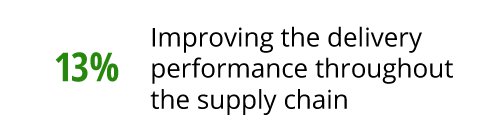

Connected SCM

App Store

Capabilities

- Stakeholder Enablement and Training

- Quality Management with External Partners

- Continuous Optimization of Supply Chain Processes

- Master Data Management

Benefits

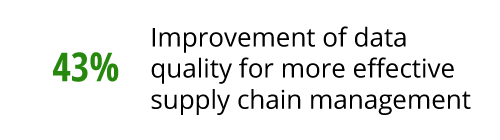

- 13% / Improving the delivery performance throughout the supply chain

- 43% / Improvement of data quality for more effective supply chain management

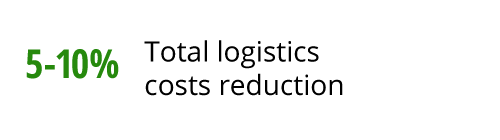

360° Control Tower

App Store

Capabilities

- Real-Time Supply Chain Monitoring

- End-to-End Performance Management

- Supply Chain Risk Monitoring

- Data-driven Optimization with Artificial Intelligence

Benefits

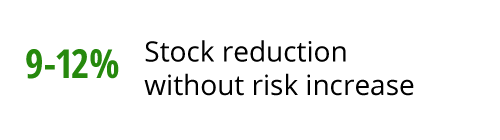

- 5-10% / Total logistics costs reduction

- 9-12% / Stock reduction without risk increase

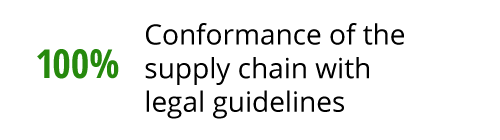

ESG Sustainability

App Store

Capabilities

- n-Tier Risk Analysis

- 360° Supply Chain Illumination

- CO2-Tracking and Optimization of the Ecological Footprint

- Circular Economy

Benefits

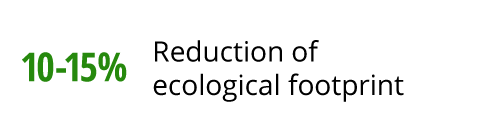

- 100% / Conformance of the supply chain with legal guidelines

- 10-15% / Reduction of ecological footprint

– Ken Engel, Senior Vice President, Internet Giants, Schneider Electric

Additional Resources